Generally in clocks if you need a new part, it needs to be made. It’s much rarer in a clock, however, that those parts are barely larger than those in a watch. I was given a Smiths mystery clock which had a damaged hour wheel and had sat on the shelf in another workshop without any work being done for some time. Time to bring this interesting object back to life!

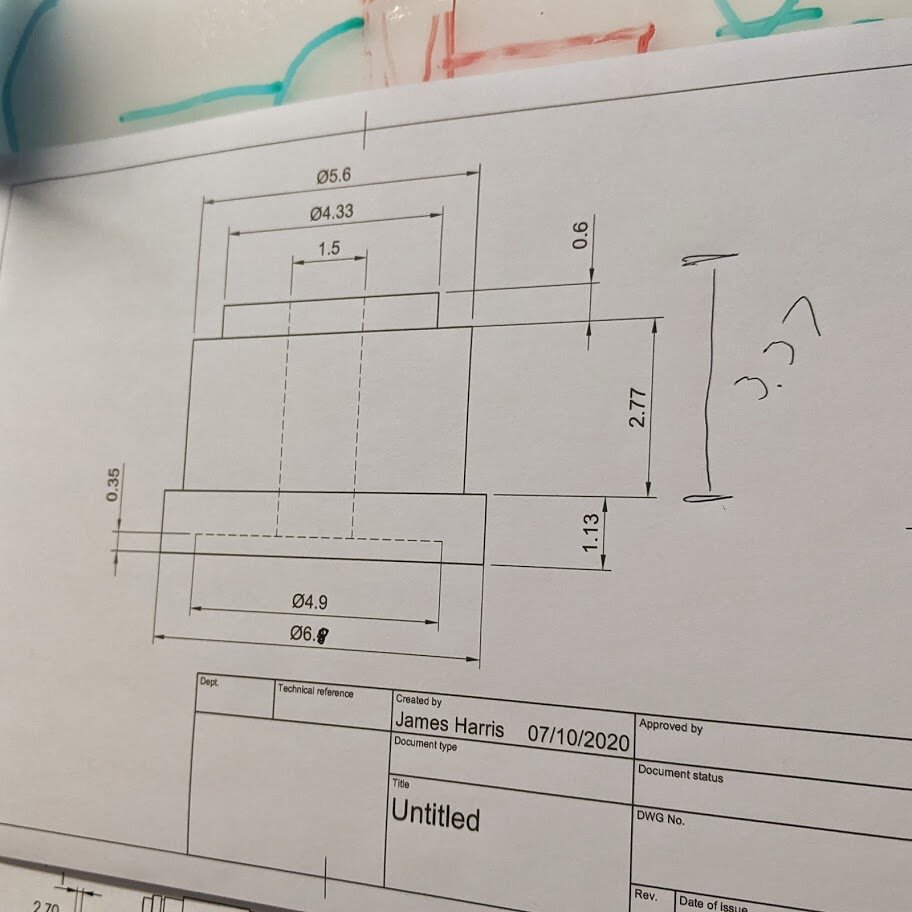

On a complex component such as this, I will always make a model and drawings first. There’s a lot to get wrong so it’s important to have a very clear drawing to follow. Having this printed and hung up on the workshop wall makes checking critical dimensions easy as a reference is always at hand.

Clock Wheel Cutting

The first operation is to cut the teeth; this wheel has 40 teeth and is just 6.8mm in diameter, which makes it incredibly challenging to make. As wheels get smaller, the level of accuracy required increases exponentially. Consider a clock great wheel - if the teeth are cut 0.1mm off centre this will be hard to see and will make very little difference to its function. On a wheel this size, however, 0.1mm will mean the teeth are noticeably at an angle and will have a significant effect. Ensuring the cutter is correctly positioned and lined up takes almost as long as actually cutting the teeth. As you’ll see below I elected to cut a longer length of bar, so I’ve got the ability to make more of these wheels in future or had spare if a mistake was made later in the process.

It’s a curious mechanism and really quite an interesting idea - round mystery clocks can quite easily be worked out with just glass wheels, but square ones clearly can’t do that. This movement rocks a glass back and forward and uses a tiny ratchet system to move the hands round, as you can see in the video below.